In the late 80’s, the growing demand of footwear soles leads to the creation of DIVISIONE STAMPI, now Frani Stampi S.r.l.

Huge investments in Computerized Numerical Control Machines, CAD/CAM software, and skilled labour create the brand new high-tech mechanical workshop.

Rubber moulds for shoe soles, TR, TPU, TPL, PU, E.V.A, PVC, direct injection moulding, moulds for plastic materials, and more…

From both technical and aesthetic consultancy, working with the most eclectic designers, to the delivery of the mould, together with modelling and 3D scanning, CAD/CAM design solutions, CNC machines, testing… the whole process is carried out within the company. Moreover, automated production phases allow Frani Stampi Srl to count on a 24/7 productive process.

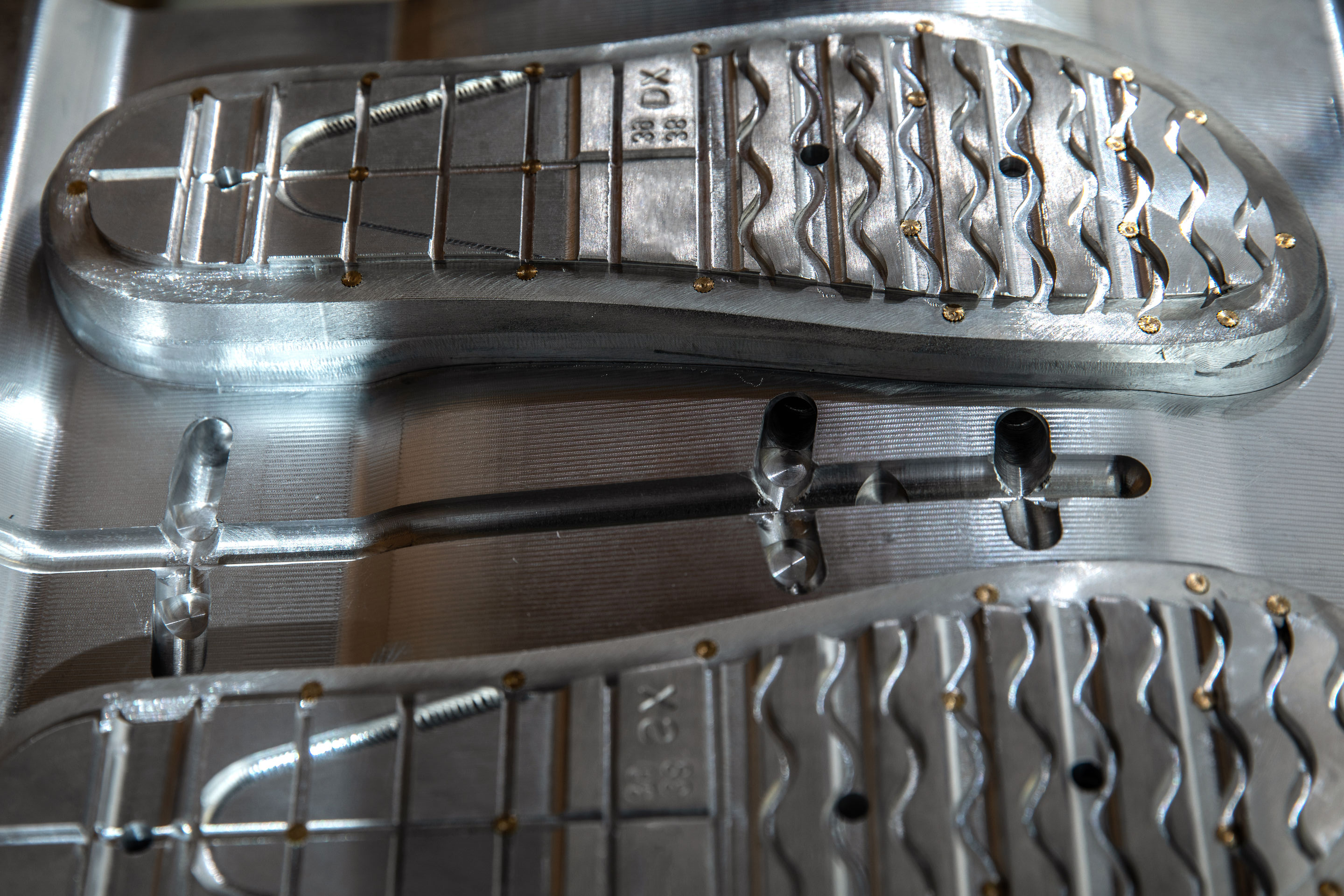

Footwear sole moulds

Given the strong presence within the footwear district of Le Marche region, Frani Stampi Srl designs and creates footwear sole moulds for every kind of material.

- PU

- TPU

- PVC

- TPL

- TR

- EVA

- RUBBER

Direct injection moulds

Frani Stampi Srl designs and creates direct injection moulds for technical, accident prevention, and sports footwear.

Available in:

- TPU-PU

- PU Rubber-PU o TR-PVC

- Depending on the customer’s request

Technical moulds

Besides the footwear industry, Frani Stampi Srl paid closed attention to designing and producing technical moulds for automotive and industrial design areas. As a matter of fact, Frani Stampi Srl has always aimed at exploring new sectors, given the strong entrepreneurial spirit.

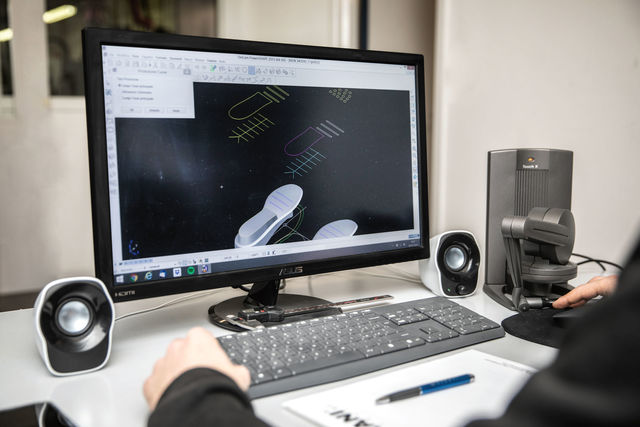

CAD/CAM design

Within the technical department, Frani Stampi Srl’s programmers put to good use their experience, mixing creativity and science; indeed, ideas take shape thanks to 3D modelling before being sent to the processing center.

CNC MACHINES

CNC machines are equipped with 3 or 5 axle-milling cutters, which allow to create all the components of the moulds in an effective, accurate, and fast way, guaranteeing a 24/7 productive process.

Workshop

With more than 50 years of experience in the mechanical industry, Frani Stampi Srl’s workers perform the operations of finishing, quality check and testing, before delivery.